Chocolate Molds

For Every Project

Jump to:

At Tomric, molds are more than what we make, they are who we are. Since the very beginning, Tomric has been designing, manufacturing, and distributing only the highest quality professional polycarbonate molds — giving us the insight and production capabilities only years of experience in business can provide.

In addition to our wealth of custom mold experience, from simple logo pieces to complex 3D designs, we are proud to offer thousands of unique molds from our expansive portfolio of stock molds as well. No matter your vision, Tomric is here to help bring it to life in chocolate.

Custom Molds

Expand

Custom Molds

When it comes to custom molds, if you can imagine it, Tomric can help you create it in chocolate. Our team has the experience and capabilities to transform almost any design into a custom polycarbonate mold. Whether you want to turn a simple logo into chocolate pieces or create a full 3D mold based off a sketch on a napkin, we can help.

Custom Molds

Quick Ship

Logo Piece

Custom Molds

Injection Molds

Custom Molds

Thermoformed Molds

Chef Collection

Expand

Chef Collection

At Tomric, we are inspired every day by the creativity and talent of our customers. When we design a new mold, we can only imagine the amazing creations chocolatiers around the world will bring to life with the molds. We started the new Tomric Chef Collection as a way for some of the most talented and innovative chefs and chocolatiers in the world to create molds that are a direct reflection of their own creativity and culinary style. Each mold is a clear representation of the chef, and we hope their designs will inspire others to create beautiful and innovative chocolate pieces with these unique molds.

Flat Molds

Expand

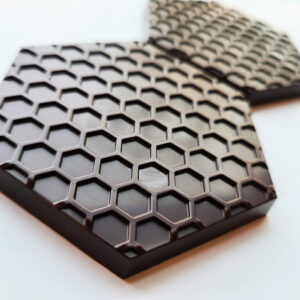

Flat Molds

This type of mold produces flat-backed pieces with a dimensional front. Although referred to as flat, these molds are capable of producing incredibly detailed and dimensional designs. In our stock line, we offer everything from simple bars and pralines, to complex recreations of animals and real-world objects.

3D Molds

Expand

3D Molds

Three Dimensional molds like the classic chocolate bunny are made using 3D molds. All 3D molds consist of two separate sculpted pieces that form the two halves of the design. Typically, the halves are held in place by magnets or clips until the chocolate has set. Most Tomric Classic and Proline 3D molds are also available as either closed bottom (for shell molding) or open bottom (for solid pieces).