Full Custom Thermoformed

Limitless Flat and Full 3D Design Options

From custom bars to elaborate 3D sculptures, our team has the skill and experience to make your vision a reality. Whether it’s just an idea in your head or an exact recreation of a real-life object, we will work closely with you every step of the way to produce a unique design to meet your exact expectations and requirements.

All our custom thermoformed molds are made from food-grade polycarbonate and are manufactured in-house at our state-of-the-art facility in Buffalo, NY. Because these molds are designed and manufactured in-house, development time is quicker and more efficient. Additionally, we store every custom tooling in our warehouse for quick and easy reruns of the mold design in the future.

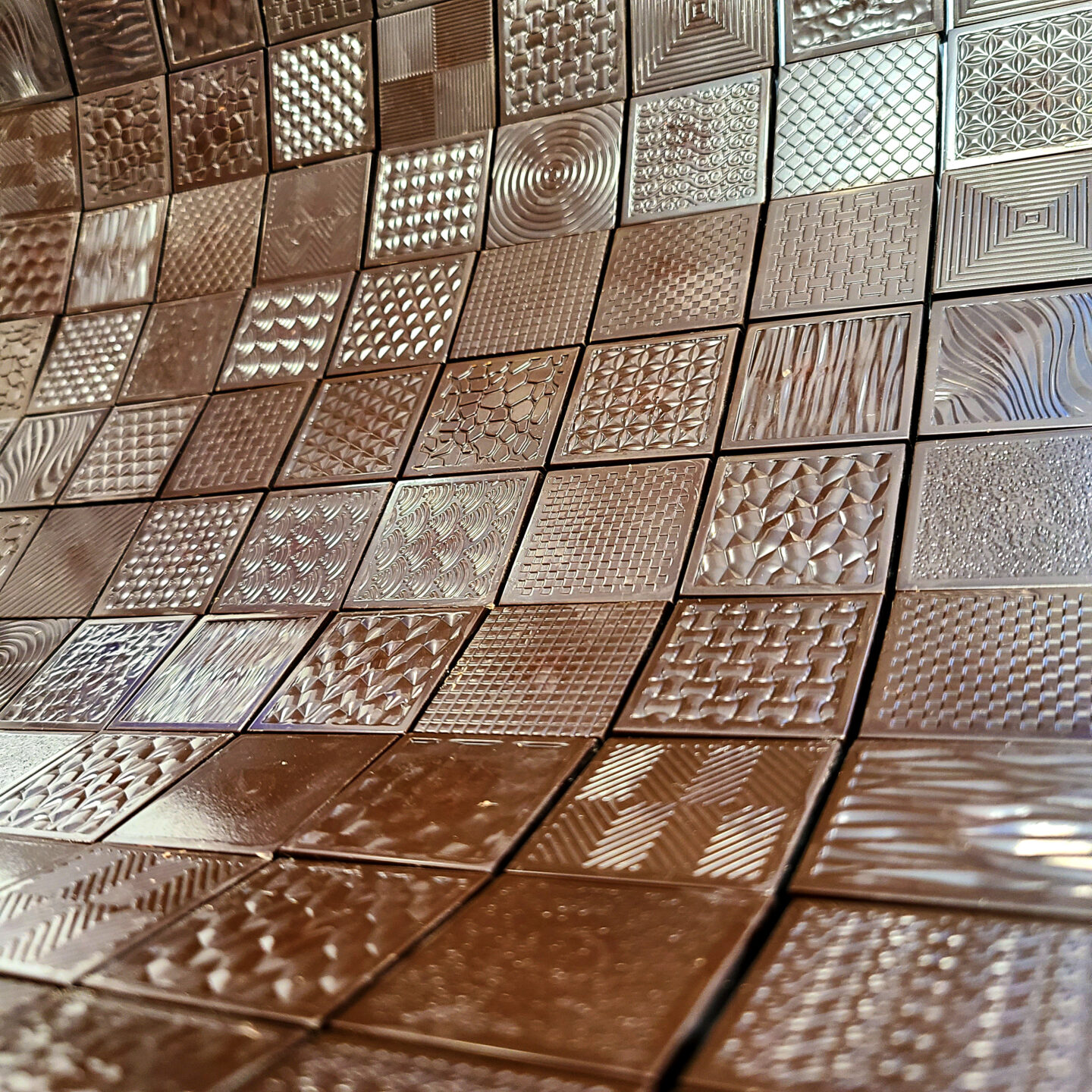

Examples of Thermoformed Molds

Thermoformed vs Injection Style Molds

At Tomric, we manufacture and sell both thermoformed style (vacuum formed) and injection style polycarbonate molds. While both types result in high-quality chocolate molds, there are a few key differences to be aware of.

- Due to the manufacturing process, injection molds are more rigid and can be used on automated lines with stackable mold loaders.

- Thermoformed molds have some flex and are ideal for anyone hand-filling molds or using a depositing head.

- Both styles can produce detailed designs, but injection molds will translate fine details and texture better.

- Thermoformed molds are typically more affordable, especially when working with large or 3D molds.

FAQs

What type of designs can be created?

Because we work directly with you to develop the mold, nearly any design is possible, including fully sculpted 3D pieces. The types of designs possible are categorized as follows:

- Bars (plain, etched, or sculpted)

- Break-up bars

- Prism/geometric designs

- Pralines/Bon bons (various shapes used for filled chocolate)

- Sculpted 3D Flat Pieces (flat-backed pieces with dimensional fronts)

- Sculpted two-piece Full 3D pieces

What size molds can we make?

With thermoformed molds, we can create almost any size from a .25” x .25” pieces – 21” x 16” pieces.

Eg: Small chunks/chocolate chips (200-300) to large slab molds in 22” x 17” pan.

What type of reference material can we use?

When creating a custom mold, we want to create a design that looks exactly how you envisioned it. This is made easier when quality reference images or materials are provided. If the idea only exists in your head, even a simple drawing is a good place to start. Documents we can accept include:

- Photographs or drawings

- Google Images

- Logos or other branding

- Layout or description of the mold

- PDF mock-ups

- .ai or .esp files (preferred)

- .jpeg. .gif, .png files (less ideal but acceptable)

- .STL or .IGES files (preferred for complex designs for CNC machine)

Please note that we can’t recreate artwork, logos, or other copyrighted materials that the customer does not own or have the rights to use.

Are there any design elements that don’t translate well on a custom mold?

While our design team can make almost any design work, some elements might require alterations. For example, extremely fine detail, undercuts or large protruding elements, very small text & text with fine serif or swirls might need to be adjusted.

Is there a minimum mold order?

Yes. All new custom thermoformed projects have a minimum mold order requirement of 20 molds. However, once the initial tooling and mold order are complete, any rerun on the design can be ordered in any amount.

How are custom projects billed?

Each custom project is completed and billed in phases. We require a deposit in Phase 1 (creation of the digital rendering) and a rough shipping amount to begin the project. If at any point the project is cancelled, we will only charge for any work completed on our end.

Ready to start a custom project or want to learn more?

Our experts are here to help.