Selmi Xform

- Creates uniform and precise shapes

- Shape and size of extruded product can be customized

- Easy-to-use touch screen controls

- Works with Selmi cooling tunnels and automatic truffle machines

Product Details

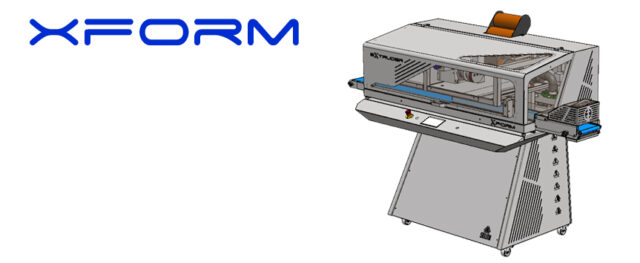

XFORM is an innovative machine designed to produce large quantities of products using specialized cylinder pastes, such as chocolate, hazelnut, almond, date, protein, superfoods, truffle, gianduja, and cereals combined with chocolate. These pre-made mixtures, created using the Selmi S9 Mould, are placed into a unique loading hopper. From there, an advanced, fully electric robotic transport system molds pralines and truffles into a variety of shapes and sizes based on the operator’s preferences.

The machine has been completely revamped and enhanced in terms of size, performance, and technological features. It includes a touchscreen panel that displays the pressure exerted by the extruder, which is synchronized with a cutting wire that shapes the products according to the selected program. This system allows for precise control over the extrusion process, enabling the operator to adjust the shape, production speed, and final weight of the products.

The XFORM extruder is also designed for easy sanitization, with simple disassembly and cleaning of its components.

For optimal results, it is recommended to pair XFORM with a cooling tunnel to solidify the shape and structure of chocolate-coated products, or with an automatic truffle machine to create truffles and truffle-filled pralines.

Features

- Creates uniform and precise shapes

- Shape and size of extruded product can be customized

- Easy-to-use touch screen controls

- Works with Selmi cooling tunnels and automatic truffle machines

Technical Information

Related Equipment

Have questions about the Selmi Xform?

Talk with our experts.

"*" indicates required fields